Objective:

To equip participants with the technical knowledge, safety understanding, and application skills needed to confidently select, demonstrate, and sell circular saw blades for various materials and cutting tasks.

Modules:

- Introduction to Circular Saw Blades:

- What circular saw blades are and where they are used.

- Overview of saw types: handheld saws, table saws, mitre saws, plunge saws, radial arm saws.

- Key performance indicators: cut quality, speed, durability, noise levels, and vibration.

- Blade Anatomy & Terminology:

Participants learn core blade components and what each part influences:- Blade Diameter – must match machine capacity.

- Arbour/Bore Size – correct fitting for safety and precision.

- Plate (Body) – steel quality, tensioning, stability.

- Kerf (Cutting Width) – thin kerf vs. standard kerf applications.

- Tooth Geometry – ATB, FTG, TCG, etc.

- Gullet Size – chip removal and cutting aggressiveness.

- Expansion Slots – noise and heat reduction.

- Types of Saw Blade Teeth & Their Uses:

Training includes a breakdown of common tooth forms:- ATB (Alternate Top Bevel) – clean crosscuts in wood.

- FTG (Flat Top Grind) – fast ripping.

- TCG (Triple-Chip Grind) – aluminium, plastics, laminate.

- ATB (Alternate Top Bevel) – clean crosscuts in wood.

- Material-Based Blade Selection:

How to match the right blade to the right job:- Wood Cutting

- Rip vs crosscut differences.

- Blades for hardwood, softwood, plywood, melamine, MDF.

- Metal cutting

- Aluminium-specific blades (TCG)

- Non-ferrous vs mild steel considerations.

- Carbide-tipped vs abrasive blades.

- Plastic & Composite Cutting

- Acrylic, PVC, fibre cement, laminate flooring.

- Specialty Cuts

- Nail-embedded wood solutions.

- Understanding Tooth Count:

- Low tooth count = faster cuts, rougher finish (ripping).

- High tooth count = cleaner finish, slower cut (crosscutting & fine woodworking).

- How tooth count affects feed rate, machine load, and heat.

- Low tooth count = faster cuts, rougher finish (ripping).

- Blade Materials & Technology:

Training includes an overview of manufacturing technologies:- Carbide-Tipped Blades – durability, edge retention.

- Diamond-Tipped Blades – abrasive materials.

- High-Speed Steel (HSS) – speciality applications.

- Laser-cut bodies & noise-reduction slots – precision and low vibration.

- Safety Training

- Correct blade installation (arbour fit, rotation direction).

- Checking for cracks, missing teeth, and warping.

- Proper PPE and safe cutting practices.

- Kickback prevention strategies.

- Machine compatibility and RPM limits.

- Correct blade installation (arbour fit, rotation direction).

- Usage Techniques & Best Practices

- How to reduce tear-out in laminated boards.

- Feed rate control for cleaner cuts.

- Reducing vibration and noise.

- Blade cleaning and pitch removal.

- How to know when a blade needs sharpening.

- How to reduce tear-out in laminated boards.

- Troubleshooting Common Problems:

Participants learn to diagnose- Burning or scorch marks.

- Excessive chipping or rough edges.

- Blade wobble or vibration.

- Slow cutting or binding.

- Tooth wear and carbide failure.

- Burning or scorch marks.

- Sales & Customer Guidance:

Training for retail or technical sales teams:- Asking the right questions to recommend the correct blade.

- Explaining the differences between premium and standard blades.

- Upselling based on longevity, cut quality, and reduced machine load.

- Educating customers on maintenance and correct usage.

- Asking the right questions to recommend the correct blade.

- Hands-On Demonstration:

- Side-by-side comparison of blade types and tooth profiles.

- Real cutting tests on various materials.

- Proper mounting and safety demonstration.

- Side-by-side comparison of blade types and tooth profiles.

- Certification:

Upon completion, participants may receive a Circular Saw Blade Product Knowledge Certificate, demonstrating:- Correct material-blade matching.

- Safety and installation competency.

- Application and troubleshooting knowledge.

- Correct material-blade matching.

Outcome:

After this training, participants will:

- Understand the full range of circular saw blades and their applications.

- Be able to advise customers or colleagues on blade selection confidently.

- Know how to use, maintain, and troubleshoot circular saw blades safely.

- Improve professional credibility and sales effectiveness.

| Event Type | Training_course |

|---|---|

| Organiser Name | Mbalenhle Maroka |

| Organiser Email | mbalenhlem@vermontsales.co.za |

| Organiser Telephone | 0113147711 |

| Dates | 2026-03-10 09:00:00 - 2026-03-10 15:00:00 |

| Class/Event Length | 6 Hours |

| Location | 192 Tsessebe Crescent Midrand Gauteng South Africa -25.949700022046105 , 28.140760817554153 |

| Seats available | 13 |

10 March 2026

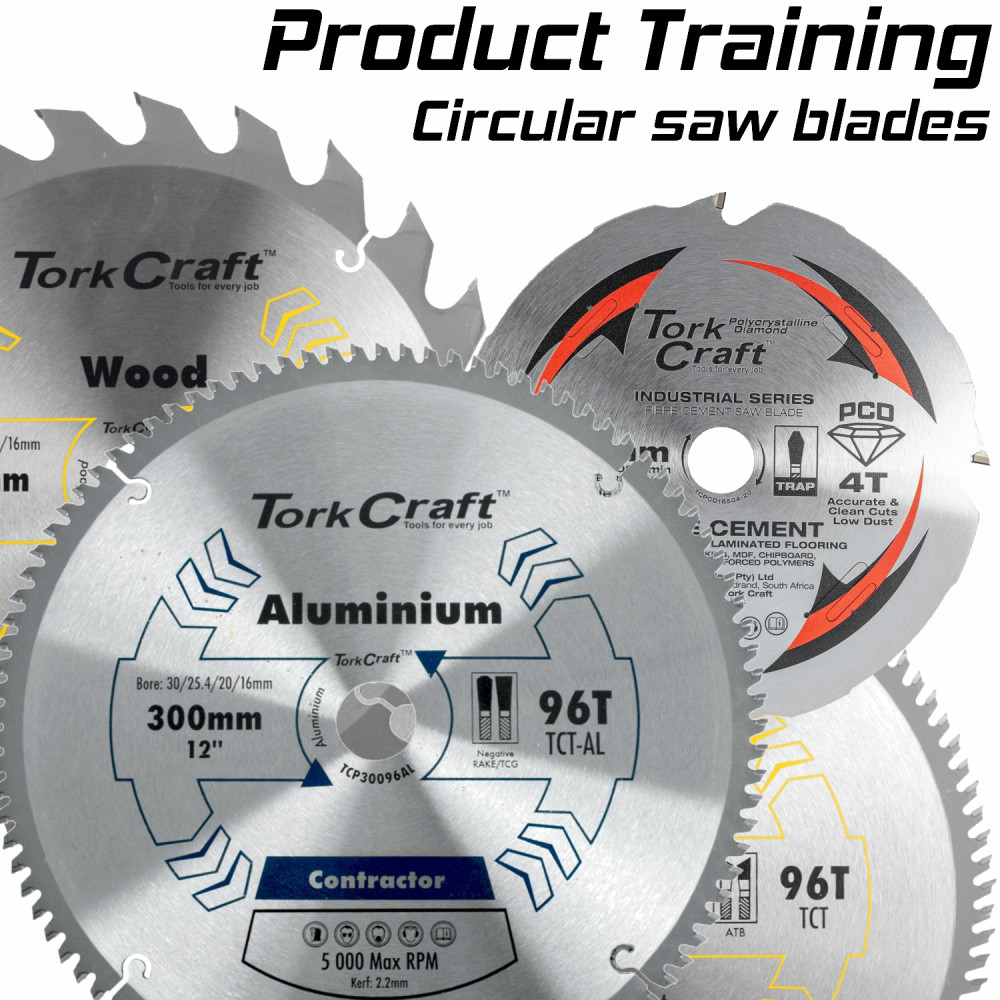

Circular Saw Blades Training - Gauteng

Available Options

Disclaimer: Please ensure that you have read and understood the terms and condition associated with this event. Please access the terms here

Tags:

Training